From Concept to Creation: The Step-by-Step Process of Manufacturing Custom Notebooks

Behind every beautifully crafted custom notebook lies a meticulous process that turns a concept into a tangible creation. In this blog post, we’ll take you on a journey through the intricate steps involved in manufacturing custom notebooks, offering insights into the craftsmanship and attention to detail that bring these unique pieces to life.

Step 1: Ideation and Design

The journey begins with a spark of creativity. Whether it’s a personal project, a corporate gift, or a branded item, the design process starts with ideation. Sketches, digital renderings, and mood boards help conceptualize the notebook’s look, feel, and functionality. This phase involves decisions on materials, dimensions, color schemes, and personalized elements.

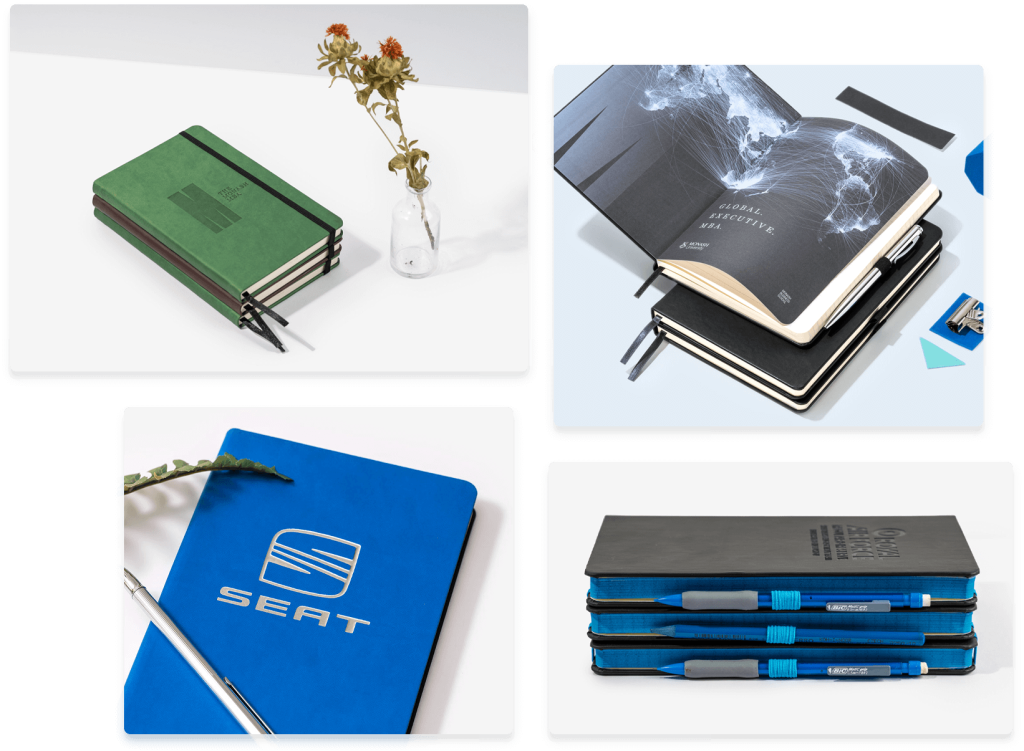

Step 2: Material Selection

The choice of materials significantly impacts the notebook’s aesthetics, durability, and user experience. The selection may include options such as vegan leather, genuine leather, cloth, or printed paper. Each material has unique qualities, and the decision aligns with the desired aesthetics and purpose of the notebook.

Step 3: Pre-Production Prototyping

Before full-scale production begins, creating a prototype is essential. This allows for a tangible representation of the design, offering an opportunity to fine-tune details, check proportions, and evaluate the overall user experience. You can make adjustments based on how the prototype looks and feels.

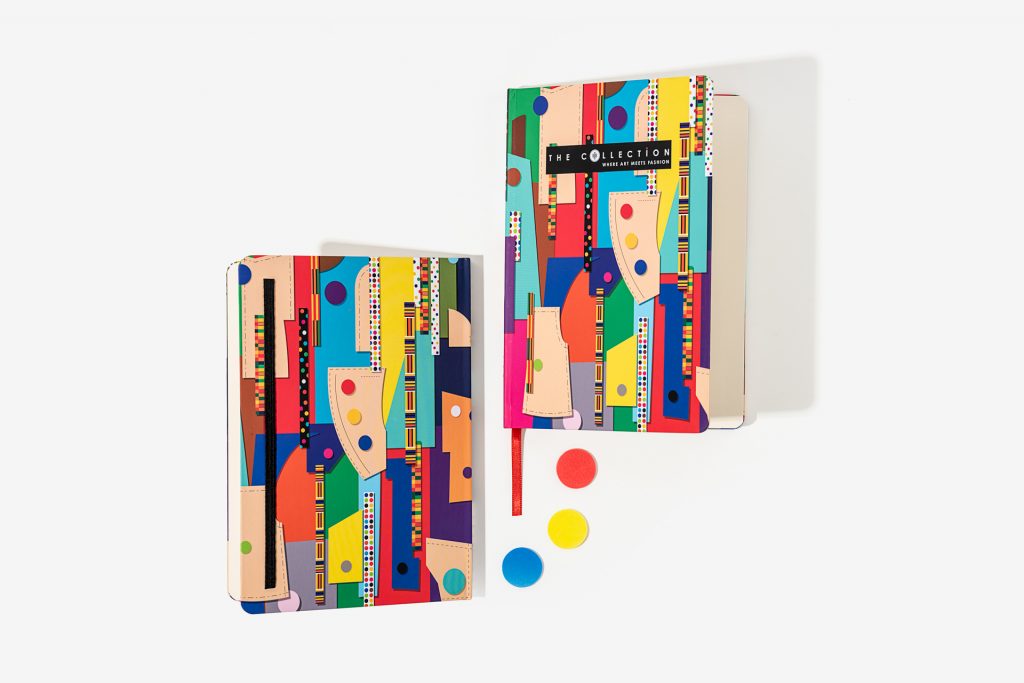

Step 4: Printing and Embellishments

If the design involves custom printing, this is the stage where it comes to life. Intricate designs, monograms, illustrations, and quotes are added through printing or other embellishment techniques. Overall, attention to detail ensures that the customization matches the envisioned design.

Step 5: Cutting and Assembly

Once we have the designs ready, we cut the material into the desired shapes and sizes. For notebooks with covers and pages, assembly begins by aligning and binding the pages. This process requires precision to ensure that pages are straight, secure, and aligned perfectly.

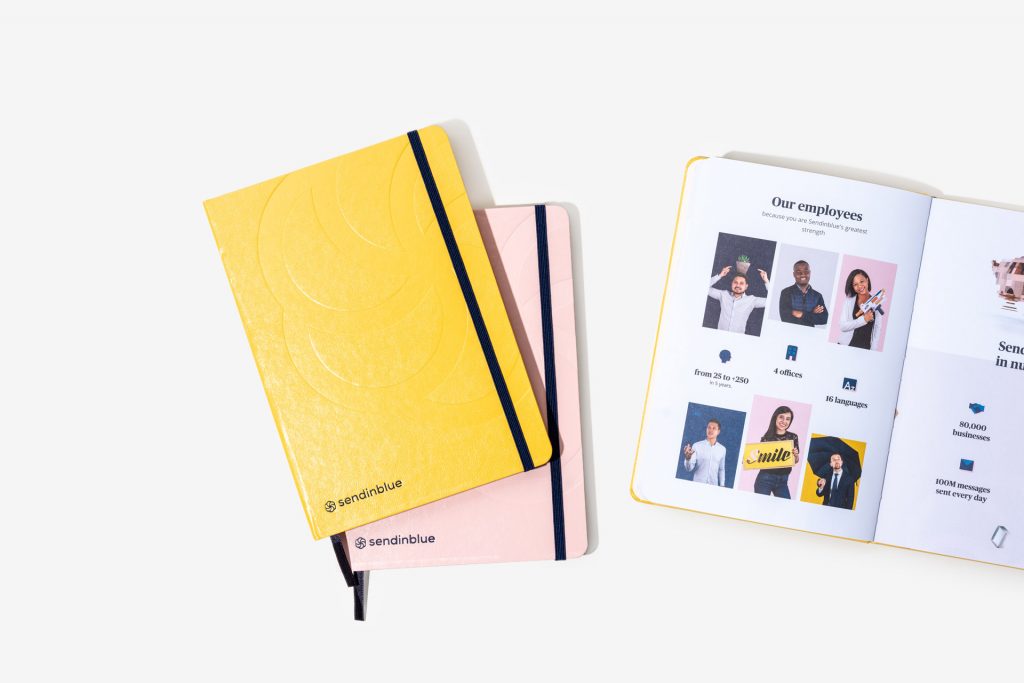

Step 6: Personalization and Customization

If personalization is a key aspect, we introduce it at this point. Monograms, initials, quotes, and other personalized elements are added to transform the notebook into a unique item that resonates with its owner or purpose.

Step 7: Quality Control

Before the notebooks are ready for distribution, they undergo rigorous quality control checks. We inspect every detail, from printing accuracy to binding integrity, to ensure that each notebook meets the highest standards.

Step 8: Packaging and Presentation

Presentation matters. Custom notebooks are carefully packaged to maintain their quality during shipping and storage. We design the packaging to enhance the overall unboxing experience, creating an emotional connection with the recipient.

Step 9: Distribution and Enjoyment

We have finalized the packaging and confirmed the quality of the custom notebooks, making them ready for distribution. Whether you decide to gift, sell, or use them for personal endeavors, these notebooks are prepared to play a meaningful role in the lives of their owners.

Conclusion: Custom Notebooks Redefined: Your Vision, Our Expertise

Manufacturing custom notebooks involves a delicate blend of creativity, craftsmanship, and attention to detail. Each step contributes to the notebook’s uniqueness and functionality from the initial concept to the final creation. Whether you choose the material, print the design, or add personalized touches, the process showcases the dedication that craftsmen invest in creating these custom companions, which hold memories, ideas, and aspirations.